Ensuring Safety and Efficiency in Chemical Plants through Drainage System Rehabilitation

“We'll deal with it later...” – these six words have cost businesses far more than they realize, especially when it comes to maintaining and upgrading critical infrastructure like drainage systems in chemical plants. Often ignored until catastrophic failures occur, outdated and inadequate drainage systems can lead to severe financial and operational consequences.

The Overlooked Importance of Drainage Systems

In many chemical industries, drainage systems are often considered secondary to other operational components. This mindset results in neglect and deferred maintenance, driven by the desire to save on costs and the "out of sight, out of mind" phenomenon. However, this negligence can have dire consequences, including:

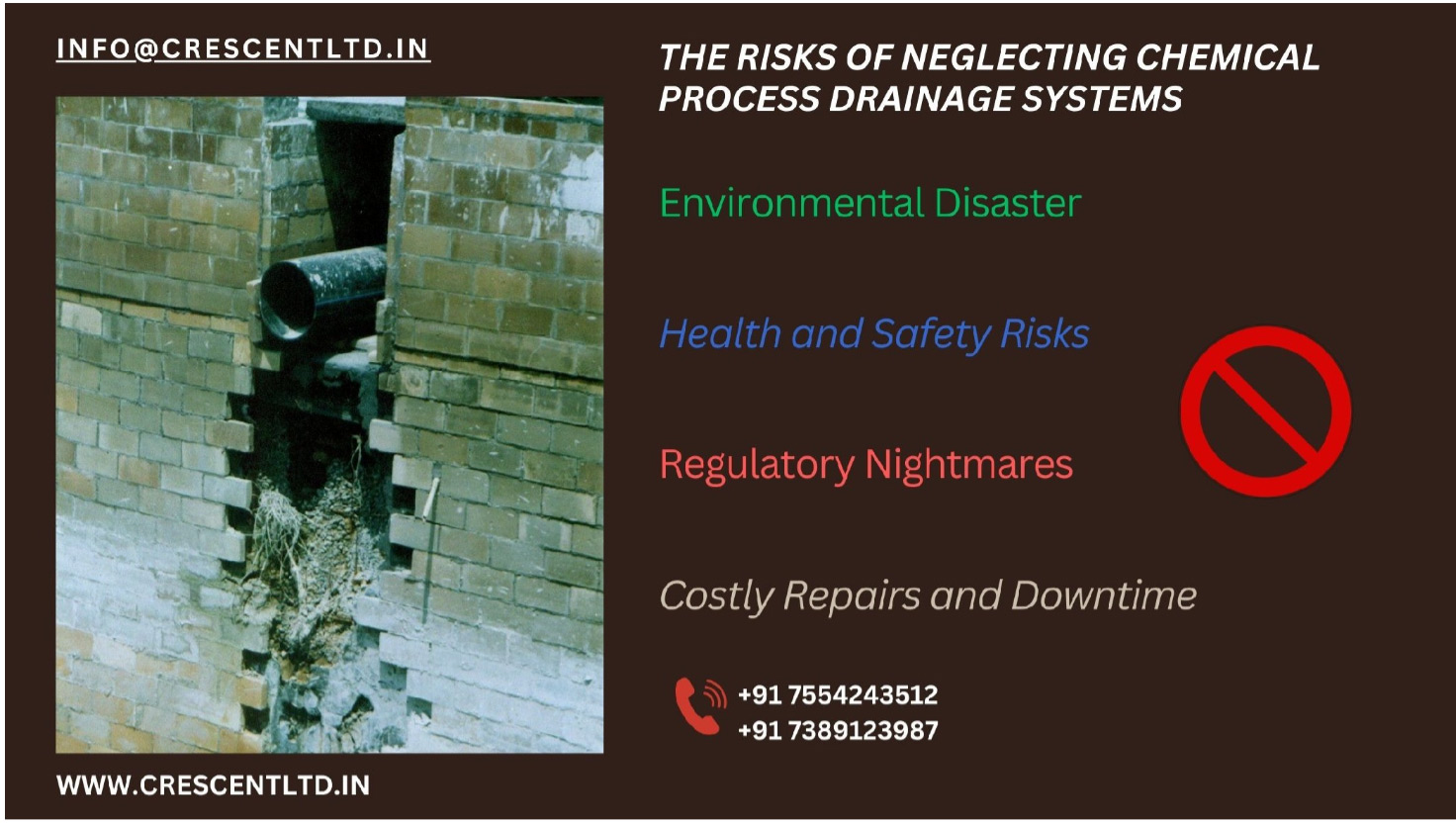

Water Accumulation and Erosion: Inadequate drainage causes water to accumulate, leading to erosion around buildings, machinery, and infrastructure. This not only weakens foundations but also creates hazardous working conditions.

Structural Damage: Persistent drainage issues can escalate, posing a serious threat to the entire structural integrity of the plant. Over time, the accumulated damage can compromise the stability of critical infrastructure, leading to costly and extensive repairs.

Legal and Financial Consequences: Failure to maintain drainage systems can result in disrupted operations, costly repairs, and fines.

Reputation Damage: Persistent drainage issues can harm a company's brand perception, affecting relationships with clients and stakeholders.

Signs of Drainage System Problems

To prevent major failures, it’s crucial to recognize early warning signs of drainage issues:

- Small leaks from pipes, joints, or drainage channels.

- Slower-than-usual water drainage rates.

- Presence of standing water in normally dry areas.

- Foul odors emanating from drainage systems.

- Formation of sinkholes or ground subsidence.

- Unexpected lush vegetation or moss growth.

Proactive Measures for Drainage Rehabilitation

Chemical plants must adopt a proactive approach to manage and rehabilitate their drainage systems:

Regular Inspections: Conduct thorough inspections to identify potential issues before they escalate.

Advanced Materials: Utilize corrosion-resistant materials for drainage systems to prevent future problems.

Scheduled Maintenance: Implement regular maintenance schedules to ensure system integrity.

Expert Consultation: Engage with industry experts to audit the drainage system and provide comprehensive reports.

Technological Integration: Integrate modern technologies like sensor-based monitoring to detect and address issues in real-time.

Conclusion

Rehabilitating drainage systems in chemical industries is not just about preventing costly repairs; it’s about ensuring the safety, efficiency, and sustainability of operations. By addressing these critical components proactively, chemical plants can avoid severe disruptions, structural damage, and create a safer working environment.

Contact Us

Need experts to audit your drainage system and provide a detailed report? Reach out to us for comprehensive solutions tailored to your needs.

.png)