Case Study

Crescent PPG With its experience and ability to think out of the box with its rich experience of more than 25 yrs., exposure to all cross section of industries, by size, product and geography can access the situation or operational requirement which is visible and hidden, analyse the same on techno commercial aspect considering the operational requirement with how it will be executed.

Crescent having an exposure (Experience of application) to all type of Chemical (Acid / Alkali) resistant Lining in general used. Different type of Lining further have different material for usage with their pros and cons. If we list out it will be more than 1000 Combinations we can offer. We start with the elimination process and finally offer 2 - 3 options with their merits and demerits to client to further evaluate and take a final call.

If situation demands we also design the solution using the combination of 2 or more type of Chemical Resistant Lining. Till date only the once we have developed the system of Chemical Resistant Lining using different material of all four types of Basic Lining, since customer has asked us need solution cost is immaterial.

1.PROCESS .DM PLANT DRAIN

Asias biggest DM Plant with 7 Streams parallel to each other, has made the situation more difficult. Cation, Anion in general is side by side or in one row of the drain. But here one after other.

All chambers were connected with each other with CW Pipe, over a period of time either the joints are opened or CW Pipes were damaged which has damaged the civil structure such badly that hardly 20-25% Chemical water reaches to the N Pit,

We have made a comprehensive study and with support of the department rectified the chambers one after another, made a full proof connection of the collection sump with Drain Pipe. Drainage system repaired to ensure 100% reaches to N Pit. By regulating the flow isolate N Pit one by one to get its repaired.

2.UREA PLANT PRILLING TOWER

Prilling Tower – 3, Hotwells Floor was constructed with Pre-Cast Slabs. There were leakages of Urea from the joints, many types of Lining were used to prevent Leakages and protection of Structure, but not yield result before its has been executed by us.

Considering the importance where height is 124Mtr repairing has to be done in Shut Down, and these leakages are harmful to the structure. We have been asked for the best.

First and till date last, we have configured the Chemical Resistant Lining system using all 4 types of Lining FRP, Sheet Base, Acid Resistant Brick and Novolac Based Epoxy used as Lining materials, to ensure it should work. Where every year repairing was required, its 3 yrs has been completed nothing has been observed.

.png)

3.SPIN BATH /PROCESS TANK

Spin Bath tank hardly of 120 SQM, since 2016 was in B/D, numbers of Lining were used which hardly serving after 3-6 months peeled off. Even that was better chemical compatible material. We have been asked in 2022, and after going through the details understand it's a problem of surface which has been contaminated such badly that even a fresh plaster applied doesn't stand well and any lining material applied peeled off.

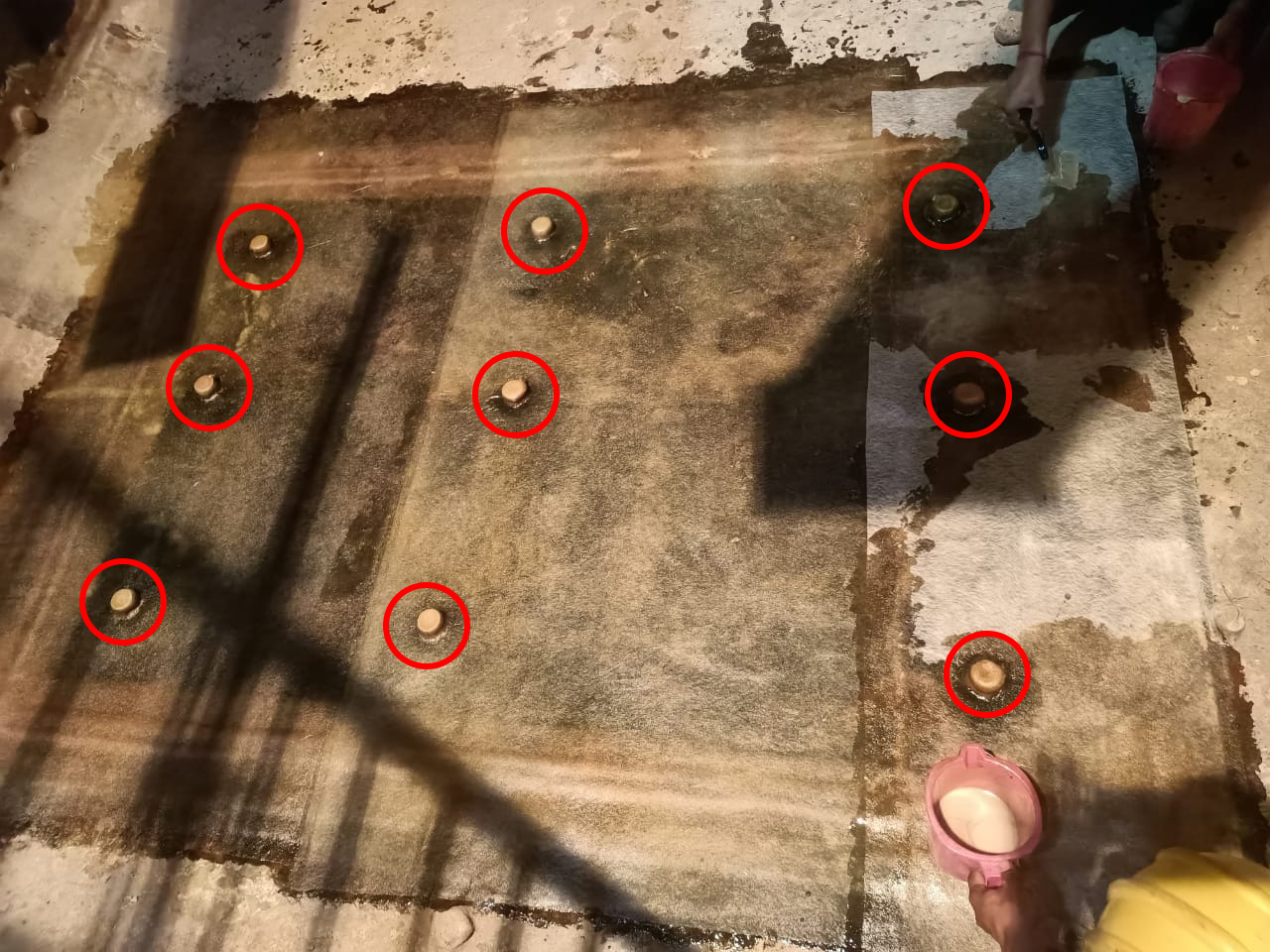

We have applied the Sheet based Lining and make an arrangement to hold it with Mechanical Fastener and ensure that Fastener should also be covered with Sheet Base Lining Material.

4.PROTECTION AGAINST GROUND WATER

After seeing best of the material and workman ship N Pit Vertical Bricks lost bonding as Ground water level has approached the N Pit from back. No lining will stand against water coming from back. We recommend usage of Polymer Based Bitumen Sheet for the same.

The water treatment plant was at low laying area, near the sea, due to that there was severe seepages in Drain and N Pit, any sort of Lining was not possible. We have been asked to take up the job, used a proper technique make it free from any seepages and provided Lining of Sheet Base.

5.SELECTION OF WRONG MATERIAL

Best quality of material has been used, Tiles were chipped out such a badly as Pointing material has reacted with chemical and leads to exothermic reaction or small level blast leads to damage to Acid Resistance Brick Lining

All joints of the Sheet base Lining damaged / cracked, PP were used which is not completable to chemical exposure and leads to damage.

.png)